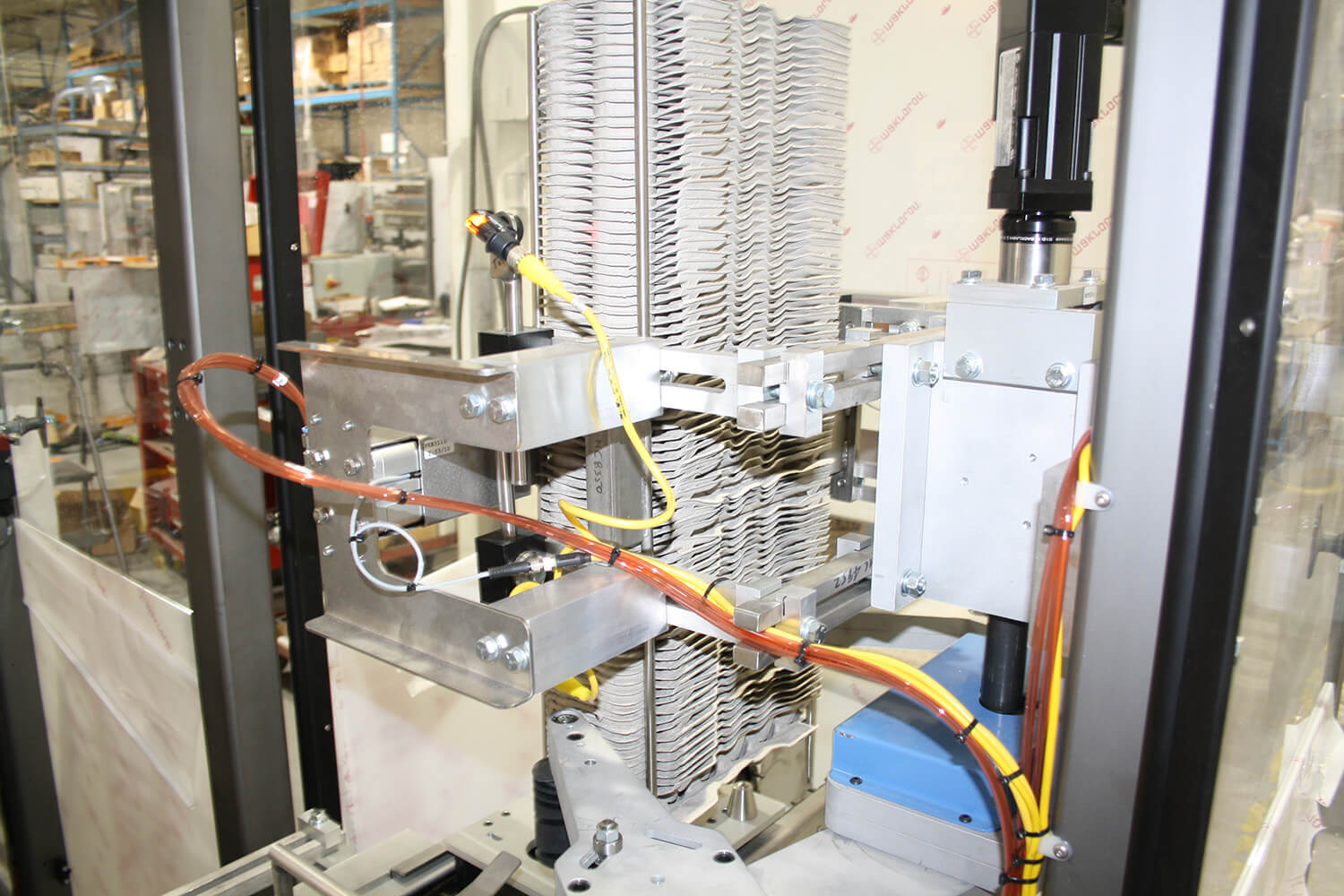

Feeders & Denestors

Compact and modular denesting systems to integrate seamlessly into your production line.

If you are looking for clamshell or coupon denesters, AFA offers compact and modular denesting systems to integrate seamlessly into your production line. We offer three different styles of denesting: reciprocating, rotary, and robotic pick and place. Each system offers various advantages for your unique application. Common applications include feeding coupons and leaflets, denesting clamshells or corrugated slipsheets, small pouches, and other applications.

Features

Integration with Other Machines

We can seamlessly integrate our feeders or denesters into major machines on the end-of-line packaging line, such as cartoners, case packers, and palletizers. For example, our leaflet feeders can integrate into a cartoner bucket conveyor to feed leaflets into buckets at speeds up to 200 leaflets per minute. Another example is a robotic end cap denestor to denest end caps and automatically places them on canisters, rolls, and other applications.

Plastic or Cardboard Clamshell Denesting

Our denestors can easily fit within your operations for manual or automatic clamshell loading. We offer reciprocating-style denestors to accurately denest and place the clamshell onto different styles of conveyors, such as flighted, tabletop chain, or belt. Our denestor units are servo-driven, providing efficient operation and accurate fault diagnostics when denesting clamshells. For more advanced applications, we can utilize AFA’s gantry robot denestors.

Compact Footprints

Our stand-alone denestors and feeders provide ultra-compact footprints which will have a minimal impact on your plant layout. If the customer is using AFA cartoners, case packers, or palletizers, we can integrate them into the machine, which will further help with floor space. Our standard magazine length is 19” but if you want more capacity then we can go to 4’ in length or greater.

High-Speed Feeding

Our rotary feeding systems can reach speeds of up to 720 products per minute. With the multi-head and multi-magazine designs, our rotary feeding systems can seamlessly interface with applications that call for multiple products loading into cartons or cases. For example, we utilized our multi-head feeder to load small pouches into cartons presented by a vertical cartoner. This design leads to a vertical cartoner running over 700 products per minute.

Engineering Capabilities

Our expert packaging engineers can design the right feeder or denestor for your unique application. Do you need a leaflet or coupon inserted in a specific position in your carton? Our expert engineers can design the appropriate to accommodate your unique packaging problems. By utilizing a built-up inventory of solutions we have developed over the years, you can be sure that AFA will have an engineered solution for your needs.