MK-SML – SERVO MANUAL LOAD CARTONER

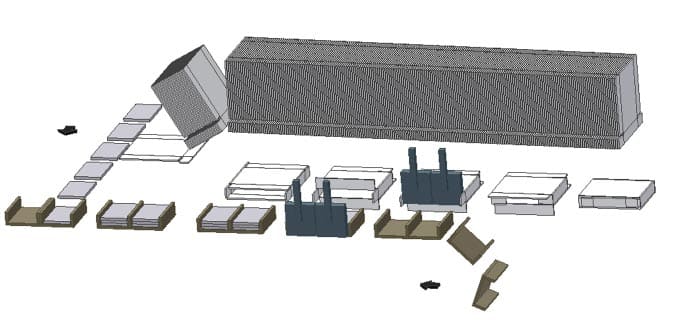

Additional equipment can be easily integrated into the system, such as labelers, printers, bar code readers, and more. This servo-driven cartoner also can feature a carton prebreak to handle square cartons. An Allen Bradley CompactLogix control system is standard on this robust cartoner.

Provides easy setup and changeover. Can allow you to manually load product at high speeds. MicroLogix or CompactLogix PLC are available. Easily troubleshoot machine problems, track machine performance, and set-up new sizes. Easily changeover and set up different carton sizes.Key Features

Servo Driven Rotary Carton Feeder

High-Speed Manual Loading Operation

Allen Bradley PLC

Intuitive Allen Bradley PanelView HMI

Easy Set Up and Changeover

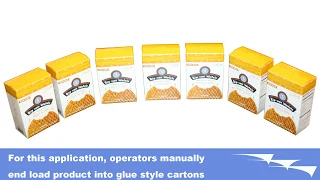

Casters allow the MK-SML to be easily moved and stored when needed. Can be easily constructed using stainless steel or equivalent for wash-down capability. Code daters, ink/laser jet printers, and bar code readers can all be mounted on the MK-SML. Can be set up to handle glue or tuck closures. Siko counters, ratchet handles, and visual scales can all be added to aid in changeover.Optional Features

Casters

Wash-down Construction

Mounting Locations for Optional Equipment

Glue or Tuck Closure

Quick Changeover Options

Applications

Bags of Product

The MK-SML is an ideal solution for high-speed bag in box applications.

Blister Packs

The MK-SML is an ideal solution for blister pack running at 80 cpm or lower.

Vacuum Sealed Product

Can seamlessly integrate with upstream automatic vacuum packaging systems.

Pouches of Product

Multi-packs or single packs, the MK-SML can handle either configuration.

Flow Wrap Product

Seamlessly integrate your upstream flow-wrappers with the MK-SML.

Partners & Associations