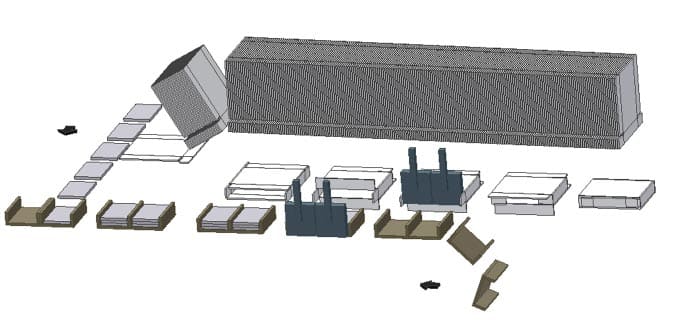

MK-BIB – HORIZONTAL / END LOAD BAG IN BOX AUTOLOAD CARTONER

The cartoner also has a minimal footprint to ensure flexibility in end user’s manufacturing facilities. The MK-BIB Cartoner can also handle one or two lanes of product to the machine allowing end-users to consolidate production lines. Also, the system utilizes multi-stage servo drop gates to provide accumulation and accurate loading into the article buckets of the cartoner.

Provides easy setup and changeover. Improves fault diagnostics and flexibility. MicroLogix or CompactLogix PLC are available on the MK-BIB. Bosch-Rexroth Linear Rail Blocks and Allen Bradley Servo Drive used to ensure minimal wear and high performance. Dual Servo Driven Drop Gate System accurately places bags of product into the article buckets.Key Features

Servo Driven Rotary Carton Feeder

Allen Bradley Servo Drives

Allen Bradley PLC

Servo Driven Barrel Cam Loading System

Customized Infeed Systems

Servo motors can be introduced on adjustment points for quick and repeatable changeover. 8ft or 4ft extended magazines are available to reduce operator intervention. Ensures cartons with long widths are accurately squared, improving overall packaging quality. The MK-BIB can be set up to handle glue or tuck closures. Overhead confiner used to compress product to ensure positive loading into tight cartons.Optional Features

Push Button Changeover Technology

Extended Magazines

Overhead Squaring Chain

Glue or Tuck Closure

Continuous Motion Overhead Confiner

Applications

Milk Powder

The MK-BIB can handle bags of milk powder at over 120ppm and with scoop feeders.

Cereal

Continuous motion cereal applications with wide size range and fast changeover.

Nutritional Supplements

The MK-BIB can easily integrate with your upstream baggers.

Health Products

Single or dual lanes to handle your bags of health product.

Frozen Foods

The MK-BIB can handle bags of product even larger than the carton.

Partners & Associations