Efficient storage is a cornerstone of successful warehouse management, and businesses are always on the lookout for smarter solutions. Gravity flow racking is one such innovative system that simplifies the way items are stored and retrieved. It uses the power of gravity to move products, making it an effortless and effective option for many industries. Whether you manage a small retail store or a large distribution center, understanding this system can help you optimize your operations.

What is Gravity Flow Racking?

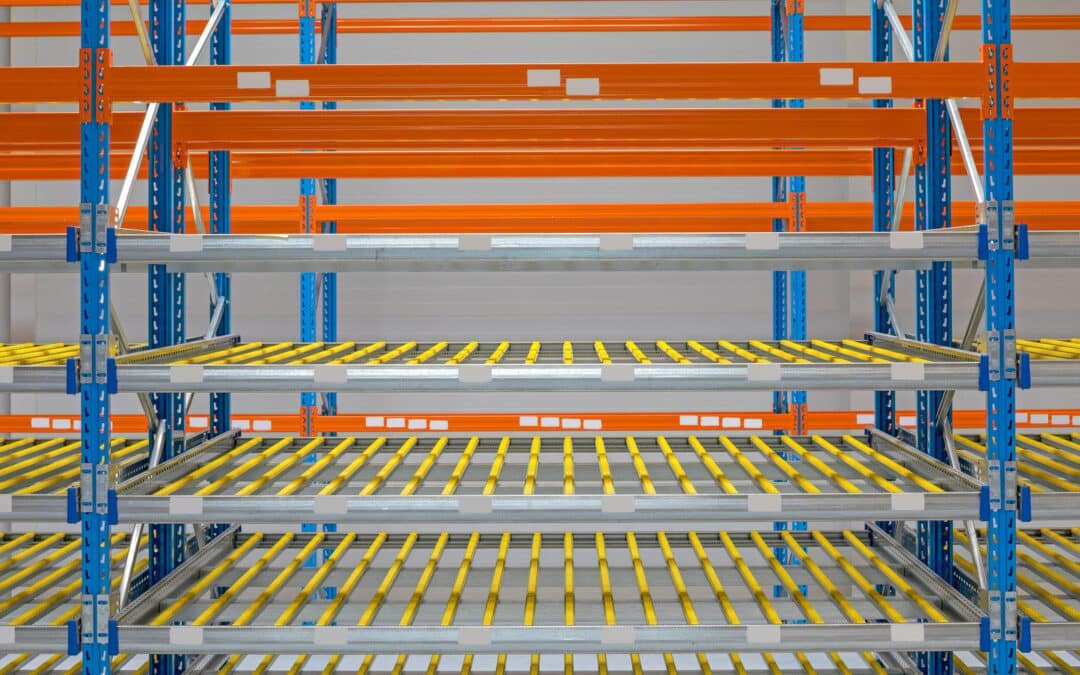

Gravity flow racking, also known as dynamic or carton flow racking, is a storage system designed to optimize warehouse operations by leveraging the force of gravity. This system uses inclined rails or rollers, allowing products to move smoothly from the loading end to the picking end. It’s widely used in industries requiring efficient inventory turnover, such as retail, manufacturing, and distribution. By facilitating a first-in, first-out (FIFO) inventory system, gravity flow racking ensures that older stock is always accessed first, minimizing the risk of spoilage or obsolescence, particularly for perishable goods or time-sensitive products.

This type of racking system is ideal for warehouses with high-volume inventory and limited space. It increases picking speed and reduces labor efforts since items automatically move to the front, ready for retrieval. Gravity flow racking systems can accommodate various product sizes and weights, making them highly versatile. Additionally, they contribute to better organization and streamlined workflows, reducing the chances of errors in order picking. With its space-saving design and operational efficiency, gravity flow racking is a cost-effective solution for businesses looking to maximize their storage and improve supply chain productivity.

How Does Gravity Flow Racking Work?

Gravity flow racking operates using a simple yet effective mechanism:

- Inclined Tracks: The racks are set at a slight incline, allowing gravity to naturally move items along the tracks.

- Rollers or Wheels: These components ensure a smooth and controlled flow of products.

- Loading and Unloading Points: Items are loaded on the higher side and retrieved from the lower side.

- Brake Systems (Optional): In some systems, speed controls or brakes are added to prevent items from moving too quickly, ensuring safety and stability.

This system can be customized to handle various types of products, including boxes, pallets, and cartons.

Benefits of Gravity Flow Racking

- Improved Efficiency

Gravity flow racking eliminates the need for manual handling during product movement. Employees can focus on loading and unloading, reducing time spent on internal transportation.

- Space Optimization

By utilizing vertical space and compact lanes, this system maximizes storage density. Businesses can store more products in less floor space compared to traditional shelving.

- Enhanced Inventory Management

The FIFO system ensures that older stock is used first, minimizing the risk of spoilage or obsolescence. This is particularly important for industries dealing with perishable goods.

- Reduced Operational Costs

Automation of product movement via gravity minimizes reliance on forklifts and other equipment. This lowers fuel consumption, maintenance costs, and labor expenses.

- Increased Productivity

Employees can quickly access items from designated pick-up points, improving order fulfillment rates and overall productivity.

- Versatility

Gravity flow racking can be adapted to various industries and product types. Whether it’s food and beverages, pharmaceuticals, or manufacturing, this system suits diverse needs.

Applications of Gravity Flow Racking

Gravity flow racking is widely used across different sectors. Here are some common applications:

1. Food and Beverage Industry

- Perishable Goods: FIFO rotation ensures fresh stock is used first, reducing spoilage.

- High Turnover: Efficient loading and retrieval keep pace with fast-moving inventory.

2. Pharmaceutical Industry

- Strict Expiry Management: Proper inventory rotation ensures compliance with regulations and prevents expired products.

- Compact Storage: Allows for high-density storage of small packages or boxes.

3. Retail and E-commerce

- Order Picking: Gravity flow racking speeds up the picking process for high-demand items.

- Seasonal Storage: Temporary use for high-demand seasons, like holidays.

4. Automotive Industry

- Parts Storage: Used to organize small and large automotive parts systematically.

- Assembly Line Support: Supplies parts directly to assembly lines for efficiency.

5. Manufacturing and Distribution Centers

- Work-in-Progress (WIP) Storage: Keeps materials organized and accessible during production.

- Bulk Storage: Ideal for managing large volumes of stock.

Types of Gravity Flow Racking Systems

Gravity flow racking systems can be tailored to meet specific storage needs. Here are some common types:

- Carton Flow Racks

Designed for lightweight items like boxes or cartons. These racks are commonly used in order-picking operations.

- Pallet Flow Racks

Built to handle heavy-duty loads like pallets. These systems are popular in warehouses managing large inventories.

- Push-Back Racking

Although slightly different, push-back racking uses gravity for compact storage of multiple pallet loads in a single lane.

Conclusion

Gravity flow racking is a practical and efficient storage solution that enhances warehouse operations. Its ability to optimize space, improve inventory rotation, and reduce costs makes it an invaluable asset for businesses. Whether you’re in retail, manufacturing, or food storage, this system provides versatility and reliability.

If you are looking for high-quality packaging solutions, AFA Systems is your go-to destination. We specialize in innovative equipment like Cartoners, Case Packers, Palletizers, Case Sealers, and Robotic Systems to meet all your packaging needs. Our advanced solutions ensure efficiency and reliability for various industries, making packaging seamless and effective.